Explore Our Latest News & Articles

After a storm, we dinghied to where a mid-forty footer had been driven ashore. Though the water level was back to normal, the water was still able to lap at the boat's keel. Not able to offer more help than being encouraging, we just walked around, checking things out.

One thing caught our attention... at the end of the boat's rode was a swivel, but just half of it. The boat's owner informed us that the other half, the 'jaws', must still be attached to the anchor, somewhere out there where the boat had been anchored.

Are you, too, thinking of using a swivel? Here are a few situations in which a swivel can be of benefit:

- The anchored boat will be subjected to more than a few cycles of reversing wind or current.

- The anchor needs to be rotated to be housed, and this cannot be accomplished by simply giving the rode a twist at the roller.

- When multiple anchors are deployed, a swivel attached to the pendant leading to the vessel can minimize twisting among the rodes.

If you do choose to use a swivel, consider the following, which, maybe, ought to be considered "rules":

WORK LOAD LIMITS (WLLs)

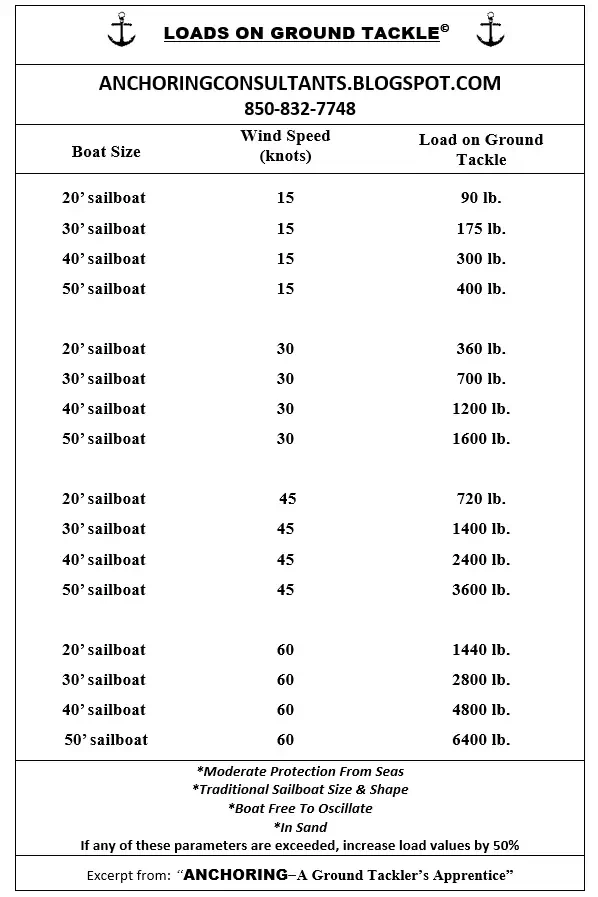

Choose only swivels that have dimensions and WLLs that match or exceed that specified by Fed. Spec. RR-C-271. Never choose a swivel based on Proof Loads (PL) or Break Loads (BL), or worse, use a swivel with no published WLL. Since load ratings are not embossed on swivels, the manufacturer's literature must be consulted for this information.

JAW DANGER

If the 'jaws' of a swivel are attached directly to the anchor, when the boat veers far enough, the jaws can jam on the anchor, resulting in bending loads on the swivel's pivot pin. This pin can break with less load than that for which the swivel is ratedas much as half. While there are several different swivel designs, all have this same vulnerability to bending loads.

Another danger with jaws involves their clevis pins, which are held in place with a cotter pin. This cotter pin can come out or be sheared off, allowing the clevis pin to back out.

REVERSE IT

With G3 (BBB/Proof Coil/Grade 30) chain a better approach is to attach the jaws of the swivel to the chain, using a shackle to attach the swivel's eye to the anchor. This arrangement provides for universal movement at each end of the swivel; but, the attendant clevis and cotter pin combination remains a risk.

However, with G4 (High Test/Grade 43/outdated Grade 40) chain this arrangement is problematic. The clevis pins in swivels with a WLL that match G4 chain are too big to fit the chain. This often leads mariners to use smaller swivels in order to get clevis pins to fit... thus, they are using swivels that are understrength, while still having the risks associated with the clevis and cotter pin arrangement.

An exception would be the stainless steel swivels manufactured by Mantus Marine, designed to overcome these problems.

BETTER YET

Another workable, and probably the most economical solution to this dilemma is to use a swivel, preferably galvanized, with an eye at each end... an eye/eye swivel. Attached with shackles this arrangement also provides for universal movement at each end, and it eliminates the risk associated with using a clevis and cotter pin. Another advantage to using this approach is that these eye/eye swivels are often available locally.

CONNECTING

In order for components to fit together and have matching WLLs, shackles, as with swivels, should be manufactured to Fed. Spec. RR-C-271; chain should be manufactured to the ISO or NACM standards.

However, there is a complication. Commonly available regular-strength (carbon) shackles fit and match the WLLs of G3 chain. But with G4 chain, when matching WLLs, the pins of these shackles will be too big to fit the chain. Therefore, a different type of shackle must be used...high-strength (alloy) shackles are the shackles to use, which are designed to fit and equal the WLL of G4 chain.

Unfortunately, high-strength (alloy) shackles often cannot be sourced locally, but, they are available online. As with any type of shackle, it might be best to keep a few extras on hand.

As a side note, we find that "U-shaped" (aka: chain) shackles, when used in ground tackle, kink much less than "bow" (aka: anchor) shackles, and as such, you may find that they are well worth the effort to obtain. Both are available galvanized as regular-strength (carbon) shackles, or as high-strength (alloy) shackles.

PINS

The threads in shackle pins often rust, or with stainless steel, gall. Wise mariners will coat these threads with Tef-Gel, grease, anhydrous lanolin, petroleum jelly, or any other applicable product to minimize or eliminate rust or galling... all require periodic renewal.

Once installed in ground tackle, pins should be safety wired (moused), even if a hole must first be drilled in the pin's tab.

WARNING SIGNS

Steel swivels, galvanized or not, have a built-in warning signal as to when they should be replaced...rust. On the other hand, a stainless steel swivel, even if made from 316L, most likely will not provide any warning that it has reached the end of its service life. Therefore, stainless steel swivels should not be used in ground tackle beyond the time frame that the manufacturer recommends. If a manufacturer cannot provide this information, then the item is not suited for use in ground tackle. This risk also pertains to stainless steel shackles, as well as stainless steel chain.

OVERSIZED LINKS

Another approach that enables the use of strong-enough regular-strength (carbon) shackles with G4 chain is to install oversized links. This can be done by local welders, machine shops, or anyone with the requisite skills and equipment.

To install an oversized link, using the largest size rod that fits the chain's link, form a link with an inner dimension that is wide enough to accept the shackle's pin, and, when installed, long enough to pass the eye of the shackle. Then insert it in the chain and weld closed; keep coated with a rust inhibitor until the chain is re-galvanized.

By now, hopefully you have identified the causes for this costly, but avoidable mishapthe 'backward' installation of a swivel, which was also undersized to begin with.

As to that boat mentioned at the beginning of this article, the owner eventually, and with significant expense was able to refloat the boat and repair the damage caused by the grounding. He also had to accept the cost of purchasing another anchor, swivel, shackles and rode.

About Rudy and Jill Sechez

Living aboard and cruising since 1997, Rudy and Jill are the authors of 'ANCHORING—A Ground Tackler's Apprentice'—available as hard copy and in the Waterway Guide Mobile App from Waterway Guide's Ship Store. Visit Rudy and Jill's website https://anchoringconsultants.blogspot.com/